The Challenger

Lawn Mower

A sunny weekend, the radio on, a beer nearby and the grass a little longer than you’d like. Rover has been quietly enabling this iconic Australian experience for over 50 years. But in 2008 when we were invited to start a conversation with them, times were rapidly changing around them and they needed to evolve to keep up.

Like many great Australian manufacturers, Rover was being challenged by changing market conditions. Their margins were being eroded by low cost Asian competitors, and high-end European and American competitors were threatening to take away precious real estate in key retail channels. They were being squeezed from both sides, and the high Australian dollar wasn’t helping.

Read More

They had responded quickly to reduce cost and gain efficiency by moving some aspects of their own supply chain to Asia. With that well underway, Rover were looking to put those hard-earned efficiency gains to work by building a substantially stronger value proposition – an innovative new hero product to reinvigorate an ageing product range.

The Challenge

Combine Rover’s 50 years of proud Australian mower development experience with CMD’s best practice customer insight, design and engineering skills to create a truly market-leading product experience to match and exceed the best in the world. Together, we set out to reinvent an iconic Australian business by designing a next generation mowing experience to take the fight back to the international market.

Rover called it The Challenger.

The Journey

As with any good design process, we started not with the product, but by trying to understand the experience of the people using the product. To move from competing on cost to competing on value for our customers, we really needed to start with the needs and desires of those customers. Although Rover had over 50 years of experience in mowers, together we really wanted to rethink the mowing experience from the grass up. So we put aside our preconceptions and approached our user observation and research as completely naive, first-time users.

Have you ever really watched people mow? It’s fascinating. When you put aside your own experience, look at it through a naive lens you start to challenge a lot of preconceptions and conventions of what the mowing experience should or shouldn’t be. After a phase of observational research the team discussed the issues associated with professional contractors needing to mow wet or damp grass.

We had witnessed how difficult it was to empty damp clumping grass from the existing catchers on the market. Rover’s research had shown that people wanted larger catchers and our intention was to deliver the largest capacity catcher to the market. However after observing this contractors difficulty in emptying wet grass we knew we had to do better. So we grabbed one of our catchers, cut it in half, put a hinge on it and reviewed it with collaborative R&D group. What if you could just press a button and your catcher would split in half? How much easier would it be to empty?

That simple insight became the patented Croc Jaw. You can’t buy the kind of gratitude that one feature gets from mowing contractors. With these insights and others, we were excited. We’d seen the best in the world and we knew we could do better.

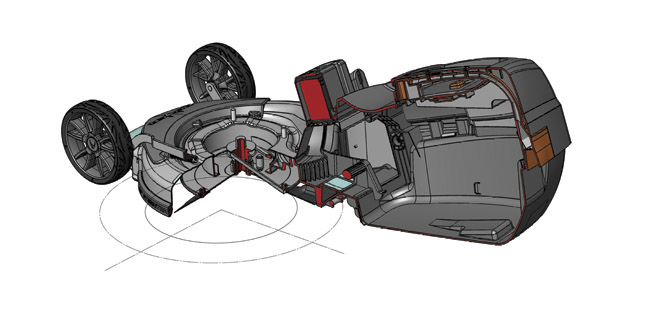

At the same time as this people-centred research, we were meticulously reverse engineering all of the leading mowers in the market. It was a bit like reading the rings in a tree we could see every detail, every decision that went into their development. Where they compromised for cost, where they over engineered for quality, where they messed up and had to fix it after the fact. Armed with that knowledge and with the strength of our network of supply partners we were able to create benchmark costs that matched or bettered the competition.

How might we curate a family of breakthrough mowers tailored to different user groups, not just one model forced upon everyone? Armed with our benchmark costs, we set after this challenge. An average car probably comes in three or four different models. In the end the Challenger had around seven models, from the cheaper model for mum and dad right up to the top of the range professional mowing contractor solution. It was quite a challenge. It wasn’t enough to design the different models so they made sense in terms of price point, functionally and value proposition. We also had to get clever in designing modular components that could be reused throughout the range, reducing tooling costs.

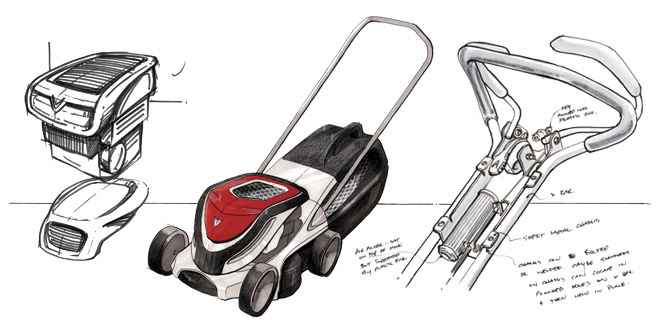

All that thinking would be useless if the mowers didn’t visually communicate their value instantly to people in stores. It takes just a glance for people to make judgements on how much they believe something is worth. So we spent a lot of time with customers understanding how they understand mowers visually. We found that people understand mowers by referencing cars and power tools (“That’s definitely the better mower, it has mag wheels like a sports car”). So we designed those aesthetic references across the product range.

As we moved into preproduction, we set about helping Rover adopt a number of new prototyping methods. It had been many years since they’d done ground-up new product development and technology had moved on. Using our knowledge of best practice engineering methods, we were able to achieve a number of technical innovations such as the use of incremental sheet forming to create a functioning and mechanically precise mowing deck prototype. This allowed us to accurately assess mowing performance, noise and vibration months in advance of receiving production ready press tool samples. Our advanced network partners from the Automotive pressing industry also helped us develop the deck design and tooling so that it could be successfully pressed full shape in a single phase. Something that Rover had not achieved in many generations of product. This allowed us to achieve a much higher quality finish, and reduce tooling costs considerably.

The Impact

When it hit the market, the Challenger outperformed all other comparable products on the market.

Amongst a long list of new features we believe the Challenger boasts:

- the largest catcher capacity

- highest cutting performance (vortex and flow rates)

- largest wheels (to reduce rolling resistance)

- the only mower able to cut right to the edge of the grass on both sides of the mower (to reduce turning and twisting)

- electric start options instead of the old “rip cord” starter

- the back saving “Croc Jaw” catcher mechanism which splits the catcher on a hinge to allow you to easily empty the high capacity catcher; and

- greatly improved ergonomic handles and general maneuverability (to minimise strain through frequent use)